| Quantity: | |

|---|---|

GROOVE ROLL SHAFT

Roll grooving machine is a specific machine for forming groove at the end of the pipe to be connected by couplings in sprinkler system, commercial heating, industry and mining etc. The pipe is supported on the inside by a knurl wheel, and the hydraulic system drives the pinch roller (also called groove roll) to the pipe. The groove is formed by the pinch roller which is fed into the pipe. Groove roll shaft is the essential part to connect the groove roll and the hydraulic system.

PRODUCT DETAILS

● Material Selection

The material low alloy carburized steel 20CrMnTi, which combines mechanical properties and low temperature impact performance, has high bending strength and wear resistance after carburizing and quenching.

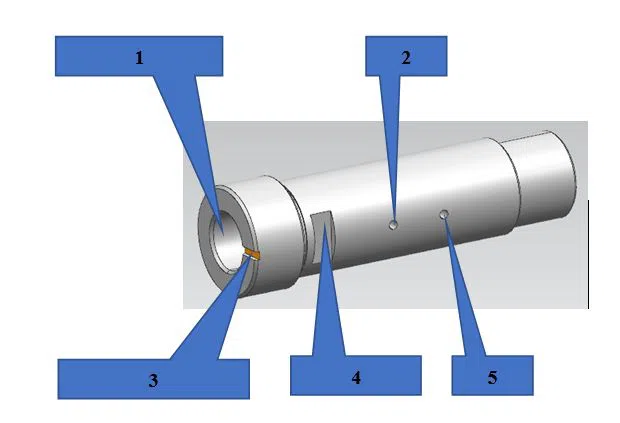

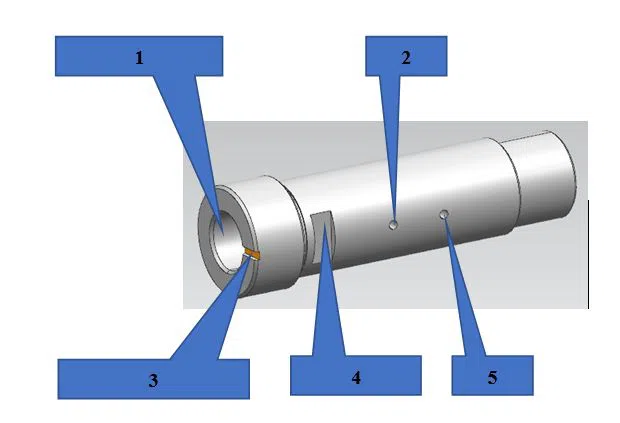

The schematic diagram of the structure

● Structure Design

No. | Description |

1 | Mounting Hole of Oil Cup M10x1 |

2 | Oil Orifice |

3 | Direction Positioning Slot |

4 | Retaining Screw Slot |

5 | Oil Orifice |

PRODUCT FEATURE

● Reasonable material selection, compact structure design and complete function.

● The processing technology is simple, the cold processing and hot processing performance is good, after carburizing and quenching, it has high bending strength and wear resistance, and has good comprehensive mechanical properties and low temperature impact performance.

● The installation and disassembly are fast, simple and convenient.

PRODUCT USE

● Groove Roll Shaft Removal

Pull the groove roll shaft retaining screw out of the pinch roller holder until it stops.

While supporting the pinch roller, remove the groove roll shaft from the slide/pinch roller holder by pulling it straight out.

Remove the pinch roller. Store the groove roll shaft inside the tool kit.

● Pinch Roller Installation

The function of the Roll Groove Shaft is to connect the pinch roller and the hydraulic pump. Below is the instruction on installation of the shaft and pinch roller.

1) Clean the roll groove shaft and pinch roller to remove any dirty before installation. Inspect the bearing inside the pinch roller for proper lubrication and condition. If damage is present, replace any affected components.

2) Carefully insert the desired size pinch roller behind the slide/pinch roller holder. Make sure the markings on the pinch roller are facing outward.

3) While supporting the pinch roller, insert the roll groove shaft into the slide/pinch roller holder and pinch roller. Tighten the groove roll shaft retaining screw to retain the pinch roller and groove roll shaft.

4) Lubricate pinch roller bearing when pinch rollers are changed by utilizing the grease ports. Use a No.2EP Lithium based grease.

5) Prior to the start of each shift, lubricate the grease nozzle/ Oil Cup M10x1 in the front of groove roll shaft after removing the dirty around the orifice.

Noted: we have it in stock so you can order it separately at any time you need.

GROOVE ROLL SHAFT

Roll grooving machine is a specific machine for forming groove at the end of the pipe to be connected by couplings in sprinkler system, commercial heating, industry and mining etc. The pipe is supported on the inside by a knurl wheel, and the hydraulic system drives the pinch roller (also called groove roll) to the pipe. The groove is formed by the pinch roller which is fed into the pipe. Groove roll shaft is the essential part to connect the groove roll and the hydraulic system.

PRODUCT DETAILS

● Material Selection

The material low alloy carburized steel 20CrMnTi, which combines mechanical properties and low temperature impact performance, has high bending strength and wear resistance after carburizing and quenching.

The schematic diagram of the structure

● Structure Design

No. | Description |

1 | Mounting Hole of Oil Cup M10x1 |

2 | Oil Orifice |

3 | Direction Positioning Slot |

4 | Retaining Screw Slot |

5 | Oil Orifice |

PRODUCT FEATURE

● Reasonable material selection, compact structure design and complete function.

● The processing technology is simple, the cold processing and hot processing performance is good, after carburizing and quenching, it has high bending strength and wear resistance, and has good comprehensive mechanical properties and low temperature impact performance.

● The installation and disassembly are fast, simple and convenient.

PRODUCT USE

● Groove Roll Shaft Removal

Pull the groove roll shaft retaining screw out of the pinch roller holder until it stops.

While supporting the pinch roller, remove the groove roll shaft from the slide/pinch roller holder by pulling it straight out.

Remove the pinch roller. Store the groove roll shaft inside the tool kit.

● Pinch Roller Installation

The function of the Roll Groove Shaft is to connect the pinch roller and the hydraulic pump. Below is the instruction on installation of the shaft and pinch roller.

1) Clean the roll groove shaft and pinch roller to remove any dirty before installation. Inspect the bearing inside the pinch roller for proper lubrication and condition. If damage is present, replace any affected components.

2) Carefully insert the desired size pinch roller behind the slide/pinch roller holder. Make sure the markings on the pinch roller are facing outward.

3) While supporting the pinch roller, insert the roll groove shaft into the slide/pinch roller holder and pinch roller. Tighten the groove roll shaft retaining screw to retain the pinch roller and groove roll shaft.

4) Lubricate pinch roller bearing when pinch rollers are changed by utilizing the grease ports. Use a No.2EP Lithium based grease.

5) Prior to the start of each shift, lubricate the grease nozzle/ Oil Cup M10x1 in the front of groove roll shaft after removing the dirty around the orifice.

Noted: we have it in stock so you can order it separately at any time you need.