Victaulic Pipe Tape – A durable, compact tool for accurately measuring pipe groove dimensions with Go/No-Go markings.

Comprehensive Overview of Pipe Tape

Victaulic Pipe Tape is a durable tool for measuring pipe groove dimensions in construction and engineering.

It features a Go/No-Go marking system to check conformance to standards.

Available in metric and imperial units, it has a sturdy zinc alloy case and clear scale, making it a compact, accurate solution for professionals using Victaulic grooving machines.

Product Category

Pipe Groove Tape Measure

Used to check if the pipe grooves conform to the Original Groove System (OGS) specifications.

Grooved Pipe Diameter Tape

Used to check if the pipe groove diameter meets the specifications, suitable for various groove standards.

Π Tape for Grooving Measuring on Pipes

Used for measuring the outside diameter of pipes and checking groove depth, ideal for construction and engineering applications.

Application

Groove Diameter Measurement

Victaulic Pipe Tape is used to measure pipe groove diameters.

It ensures pipes meet Original Groove System (OGS) standards.

Checking Pipe Conformance

The tape features Go/No-Go markings.

It helps confirm that grooves meet specified tolerances.

Pipe Installation Preparation

The tape is used before pipe installation.

It checks groove depth and ensures proper fit.

Construction and Engineering

The tape is commonly used in construction and engineering.

It aids in the installation of grooved pipes.

Product Advantages

By measuring grooves accurately before installation, the tape helps prevent costly rework and ensures proper pipe fittings, improving overall workflow efficiency and reducing downtime.

1. Accurate and Reliable Measurements

Victaulic Pipe Tape ensures precise groove measurements, meeting OGS standards to prevent installation issues and ensure reliable fittings.

2. User-Friendly and Efficient

With clear Go/No-Go markings and a compact design, the tape is easy to use on-site, allowing workers to quickly verify dimensions and adjust as needed.

3. Durable, Versatile, and Portable

Housed in a zinc alloy case, the tape is built to withstand tough conditions and is available in both metric and imperial units, offering portability for international projects.

Victaulic Pipe Tape FAQs: Everything You Need to Know

1. What is Victaulic Pipe Tape used for?

Victaulic Pipe Tape is used to measure pipe grooves and ensure they conform to the Original Groove System (OGS) standards. It helps verify groove dimensions for proper pipe installation.

2. How do I use Victaulic Pipe Tape to measure grooves?

Wrap the tape around the pipe groove and overlap the ends. Pull both ends firmly to ensure the origin arrow aligns with the "Groove Diameter Range" band for conformance.

3. What sizes of pipes can Victaulic Pipe Tape measure?

The tape is suitable for pipe sizes ranging from DN20 to DN600 (¾” to 24”), covering a wide range of pipe diameters.

4. Can Victaulic Pipe Tape be used in harsh environments?

Yes, the tape is housed in a durable zinc alloy case, making it resistant to wear and tear in tough working conditions commonly found on construction sites.

5. Is the Victaulic Pipe Tape available in different measurement units?

Yes, Victaulic Pipe Tape is available in both metric and imperial units, providing flexibility for international projects and different pipe size standards.

Usage Guidelines

1. Remove all loose dirt, scale, and paint from the pipe surface. Choose the appropriate side of the tape. Wrap the tape around the pipe, and overlap the two ends, as shown below. Make sure the tape is not twisted.

2.When using the tape to measure the outside diameter, firmly pull on each end of the over-lapped tape. Determine if the origin arrow is within the “Pipe OD Range” band for the applicable pipe size. The origin arrow must be within this band to meet specifications.

Leading Manufacturer of Pipe Tape:

Meeting Demands and Continuous Improvement

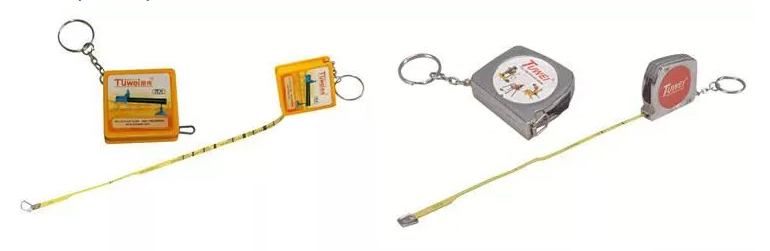

VictaulicTuwei began exporting grooving machines in 2006. In response to customer demand, Tuwei started producing grooved measure tapes in 2008, launching the first batch in 2009. Initially, tapes had a plastic cover, but due to durability issues, a metal cover was introduced in 2013. By 2017, accuracy improved with the third version. Each Tuwei grooving machine now includes a measure tape in the tool bag for convenience, alongside other tools for easy groove inspection and seal ring replacement.

Related Blogs

Keep in touch with us

If you have any inquiries or needs regarding Victaulic Pipe Tape, don’t hesitate to reach out to our customer service team. Our experienced team is ready to provide you with comprehensive product details and assist you with any questions you may have.

● Phone: +86-13634093837

● Email: li.chen@cntuwei.com