Comprehensive Overview of Manual Roll Groover Solutions

Why Choose a Manual Roll Groover? Key Advantages Explained

· Portability & Versatility

· Wide Compatibility & Precision

Designed for carbon steel pipes from 3/4 inch to 8 inches in diameter, this tool covers a broad range of applications. Equipped with a graduated circle for groove depth adjustments, it provides precise control, ensuring consistent, high-quality grooves every time.

· In-Place Grooving & Reliable Performance

Ideal for fixed pipe scenarios, the Manual Roll Groover is built for in-place grooving during maintenance. Supported by Victaulic-Tuwei's innovative design and manufacturing, it delivers reliable, cost-effective performance that meets international quality standards.

Detailed Product Showcase: Manual Roll Groover Lineup

Guide to Selecting the Right Manual Roll Groover for Your Needs

· Pipe Size Compatibility

· Operation Mode

If you require a tool that can be both manual and power-driven, look for models like the TWG-11A, which offer dual functionality.

· Portability Needs

For on-site applications, opt for a lightweight and compact model to ensure easy handling and transport.

· Precision Requirements

Choose a groover with a precision adjustment system, such as a graduated circle, to achieve the desired groove depth consistently.

Leading Manufacturer of Manual Roll Grooving Machines: Precision and Innovation

As a leading Manual Roll Groover manufacturer, Zhejiang Victaulic-Tuwei Piping Equipment CO., LTD stands at the forefront of the industry with over 15 years of experience and a strong partnership with Victaulic. Our American-Sino joint venture combines cutting-edge technology and expertise, delivering innovative products that set new standards for quality and performance. With a wide-reaching sales network spanning Europe, America, Southeast Asia, and the Middle East, our grooving machines are trusted by professionals worldwide. We prioritize precision, reliability, and customer satisfaction, ensuring you receive top-tier solutions for all your piping needs.

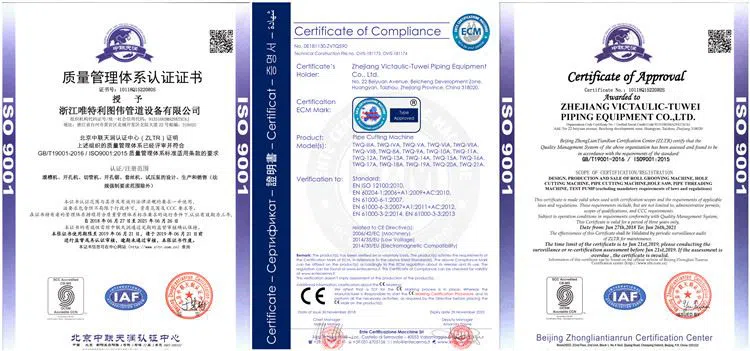

Certified Quality Assurance: CE-Approved Manual Roll Groovers

All our Manual Roll Groovers are CE-certified, adhering to strict international quality standards. At Victaulic-Tuwei, we emphasize rigorous testing and quality control in every stage of production. Our commitment to innovation and excellence is demonstrated through our extensive patent portfolio, including Patents for Invention, Utility Models, and Design. With certified quality assurance, you can trust our roll groovers for safe and efficient performance in any project setting, whether it's for pipe installation, maintenance, or industrial applications.

Expert Services for Manual Roll Grooving Machines

Custom Design Solutions

Our technical team can tailor grooving tools based on specific customer requirements.

After-Sales Support

We offer dedicated after-sales service to resolve any issues promptly and ensure optimal performance of your equipment.

Training and Consultation

Benefit from expert guidance on the operation, maintenance, and selection of roll grooving tools, maximizing the efficiency and lifespan of your equipment.

Manual Roll Groover FAQs: Everything You Need to Know

Q1: What pipe sizes can the Manual Roll Groover handle?

A: Our manual roll groovers are compatible with carbon steel pipes ranging from 3/4 inch to 8 inches, providing versatility for various industrial applications.

Q2: Can the Manual Roll Groover be used with power drives?

A: Yes, our models like the TWG-11A come with an adapter, allowing integration with power drives such as the RIDGID 300, transforming the manual tool into an electric roll groover.

Q3: How do I measure the groove depth?

A: The groove depth can be measured using the graduated circle on the tool, with each full turn of the feeding nut adjusting the depth by 1.5mm.

Q4: What is the weight of the Manual Roll Groover?

A: The tool weighs only 12.4 kg, making it highly portable and easy to maneuver on-site.

Q5: Is the Manual Roll Groover suitable for in-place grooving?

A: Yes, it is specifically designed for in-place grooving, ideal for maintenance tasks where pipes cannot be removed.

These FAQs cover the key aspects of our Manual Roll Groovers, helping you make informed decisions and optimize your piping projects.