Hole Cutting Machine – High Efficiency & Portability

Introduction to Hole Cutting Machine

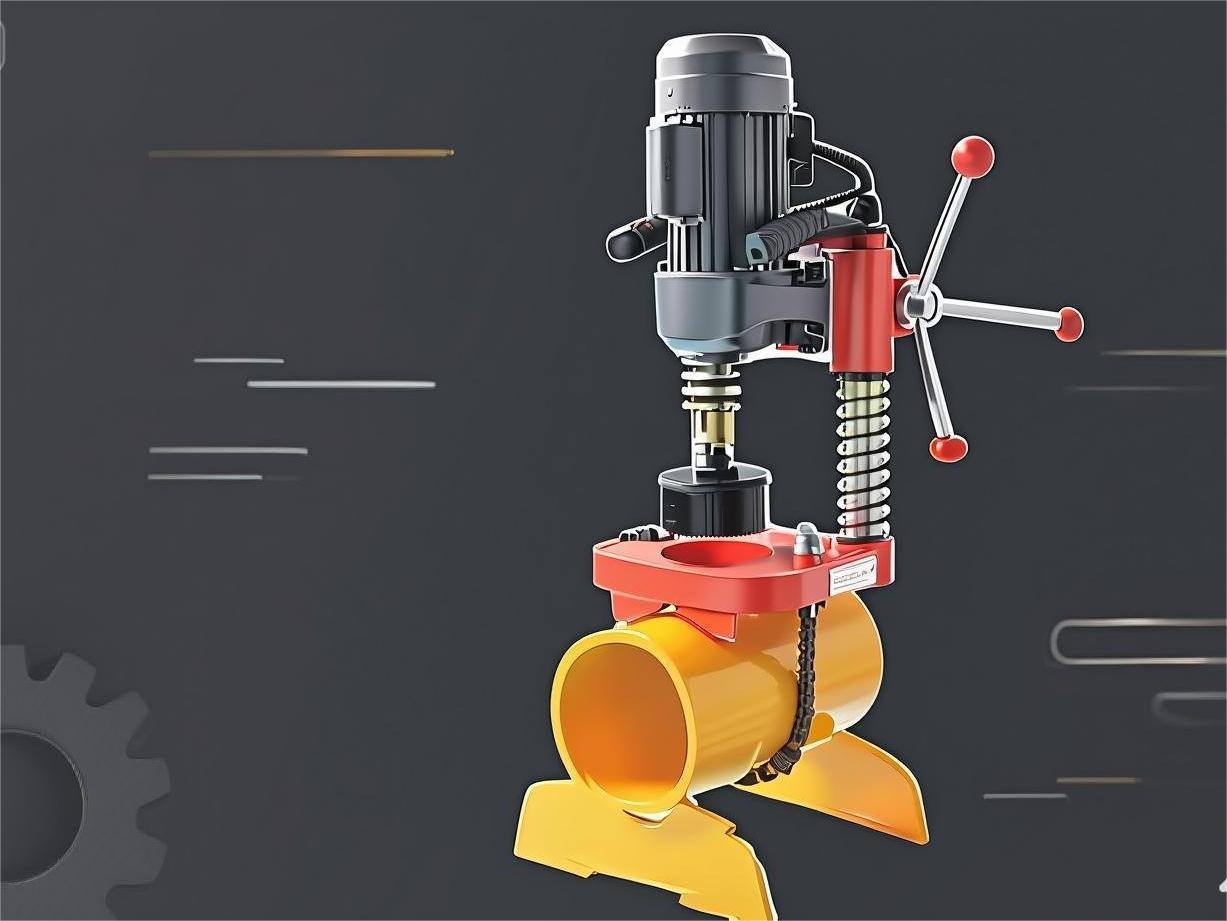

The Hole Cutting Machine is an essential tool for efficient and precise pipe cutting in various industrial applications. Designed to handle a range of pipe materials, including steel and plastic-lining pipes, it offers high performance with adjustable motor speed, ensuring optimal results across different hole sizes. This versatile machine is perfect for pipe installation and maintenance, providing accuracy and ease of use.

As a trusted manufacturer of cutting-edge pipe cutting equipment, we offer a range of high-quality Hole Cutting Machines that meet the needs of both professionals and industries. Built with durable components and engineered for reliability, our machines ensure superior performance in demanding environments.

Hole Cutting Machine

Technical Specifications

Our High Power SMD Resistors are manufactured with strict quality control, ensuring durability and compliance with industry standards.

| Pipe Diameter | 1" to 24" (25mm to 600mm) |

| Pipe Length | Customizable depending on your requirements |

| Cutting Thickness | Up to 1" (25mm) for steel, stainless steel, aluminum, and other materials |

| Precision | ± 0.5mm |

| Cutting Speed | Up to 12 meters per minute, depending on material and thickness |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Copper, and other metal alloys |

| Safety Features | 1. Automatic Shut-off for error detection2. Emergency Stop Button3. Protective Enclosures around cutting area |

Precision Engineering

With adjustable motor speeds and a built-in gradienter, our machine guarantees precise hole positioning, improving cutting accuracy and enhancing overall performance on the job site.

Why Choose Our Hole Cutting Machine?

Durability and Reliability

Designed for tough work environments, the Hole Cutting Machine is made with high-quality materials that ensure long-lasting durability, even under heavy-duty use, reducing downtime and maintenance costs.

Portable and Easy to Use

The compact and lightweight design makes our Hole Cutting Machine easy to transport and use in tight or hard-to-reach spaces, improving work flexibility and efficiency.

Industry-Leading Expertise

With over 15 years of experience in manufacturing high-quality pipe cutting equipment, we ensure that our products meet the highest standards of performance and reliability, backed by expert support and customer service.

Customizable Solutions

We offer tailored solutions, including different cutting capacities and specifications, to meet the specific needs of your project, ensuring you get the best possible fit for your requirements.

Applications of Hole Cutting Machine

The Hole Cutting Machine is an essential tool for efficient and precise hole drilling in various pipe materials, offering versatility and reliability across multiple industries.

Below are some key application areas:

Construction & Pipe Installation

The Hole Cutting Machine is widely used in construction projects for cutting holes in plastic and steel pipes, facilitating smooth installation and maintenance of pipe systems in buildings and infrastructure.

Oil & Gas Industry

In the oil and gas sector, the machine is employed for precise hole drilling in pipes during pipeline construction and maintenance, ensuring effective flow control and system integrity.

Utility Services

This machine is ideal for use by utility service providers for cutting holes in pipes for various applications, such as water and sewage systems, ensuring efficient installation and repair operations.

Automotive & Manufacturing

In automotive manufacturing and heavy machinery maintenance, the Hole Cutting Machine is used to prepare pipes for assembly or modification, ensuring precision and high-quality performance in production lines.

HVAC Systems

The machine is also used in the HVAC industry to cut holes in pipes during the installation and servicing of heating, ventilation, and air conditioning systems, offering a reliable and efficient cutting solution for contractors.

Quality Assurance & Certifications

Frequently Asked Questions (FAQs)

Q1: What makes the Hole Cutting Machine different from other pipe cutting tools?

A1:The Hole Cutting Machine is designed for high precision and versatility, capable of cutting holes in various materials, including steel and plastic-lined pipes. Its adjustable motor speed and gradienter ensure efficient and accurate cutting, making it suitable for a wide range of applications in industrial settings.

Q2: Is the Hole Cutting Machine suitable for all pipe materials?

A2:Yes, the Hole Cutting Machine is designed to work with plastic pipes, plastic-lining steel pipes, and steel pipes, making it a versatile tool for various pipe cutting tasks across multiple industries.

Q3: Can I adjust the motor speed for different hole sizes?

A3:Absolutely. The Hole Cutting Machine features adjustable motor speeds to accommodate different hole saw sizes, ensuring optimal performance for various drilling tasks and pipe materials.

Q4: How long will it take to receive my order?

A4:Lead times for orders typically range from 2-4 weeks, depending on the order volume and any customization requirements. We will provide you with an estimated delivery date upon order confirmation.

Q5: Do you offer engineering samples for testing?

A5:Yes, we provide engineering samples for qualified projects, allowing you to test the Hole Cutting Machine before placing a bulk order. Please contact us to request a sample.

Related Blog

How Does a Hole Cutting Machine Improve Precision in Metal Fabrication?

How to Order

We provide flexible ordering options to meet your project demands. Get started today by selecting from our available products or requesting a custom quote:

"Get a Free Quote Now" – Quick and easy quotation process

"Download Product Datasheets" – Access detailed technical information

"Request a Sample" – Try before you buy

Mob:+86-13634093837

E-mail:li.chen@cntuwei.com